- Home

-

Product

Turning

Turning Series is engineered for high-precision and high-efficiency turning, including Boring Tools, Quick Change Boring Tools, Turning Inserts, and Knurling Tools. It delivers complete machining solutions for CNC lathes, automatic lathes, and Swiss-type machines.All tools are made from premium carbide and produced with precision processes, offering excellent rigidity, stability, and wear resistance for consistent performance in high-speed and high-volume machining. Boring and Quick Change Boring Tools ensure accuracy in small-diameter and deep-hole operations while reducing tool-change time. Turning Inserts feature multiple geometries and coatings for stable roughing and finishing across various materials. Knurling Tools provide clean, precise anti-slip and decorative patterns.Overall, the Turning Series enhances machining efficiency, dimensional accuracy, and surface quality.

Milling

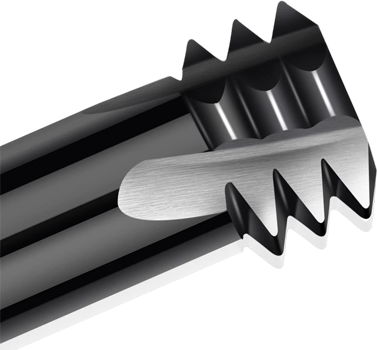

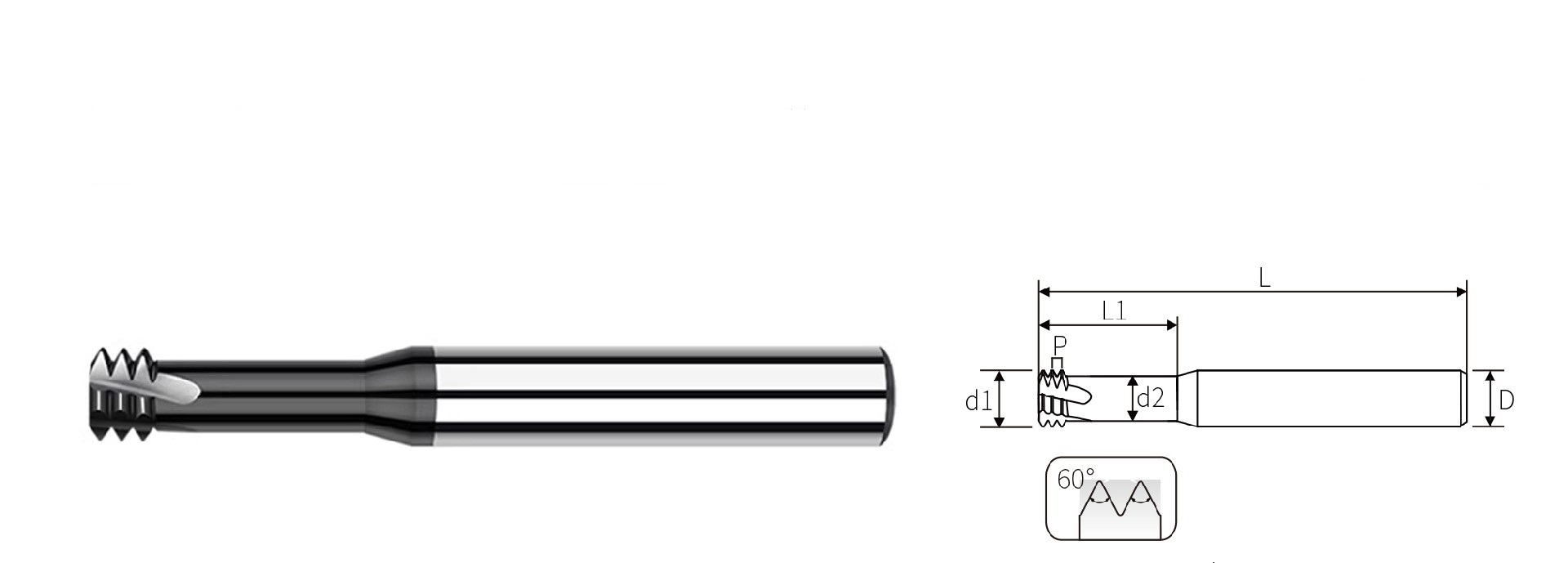

Milling Product Series is designed for high-precision, high-efficiency CNC machining across a wide range of materials, including carbon steel, alloy steel, stainless steel, titanium alloys, and composites. Using premium materials and advanced manufacturing technology, the tools deliver excellent dimensional accuracy, stable cutting performance, efficient chip evacuation, and long tool life for both roughing and finishing operations.Carbide End Mills are made from ultrafine-grain solid carbide, offering high hardness, wear resistance, and optimized flute geometry for smooth cutting, reduced vibration, and extended service life. They are well suited for high-speed machining in molds, aerospace, medical, and precision engineering applications.Diamond End Mills are ideal for ultra-hard and abrasive materials such as graphite, ceramics, carbon fiber, and non-ferrous metals. Diamond coatings provide exceptional durability, thermal stability, and superior surface finish for ultra-precision and long-cycle machining.Carbide Thread Mills enable accurate, burr-free internal and external threading with high stability. Compared to traditional taps, they offer safer machining, greater flexibility, and reliable results in tough materials and complex threading applications.Overall, the Milling Series supports higher productivity, lower machining costs, and superior surface quality in modern CNC manufacturing.

Drilling

Drilling Series is developed for high-precision, high-efficiency metal drilling in CNC machining centers and automatic lathes, especially for demanding and hard-to-machine materials. With optimized cutting geometry, advanced tool materials, and high-performance coatings, the series ensures stable drilling, excellent hole quality, and long tool life.The series includes Carbide Drills and Diamond Drills.Carbide Drills offer high hardness and wear resistance, making them suitable for steel, stainless steel, aluminum alloys, and heat-resistant materials. Their optimized cutting edges provide smooth chip evacuation, high dimensional accuracy, and stable performance in deep-hole, micro-hole, and batch drilling operations.Diamond Drills are designed for high-hardness and brittle materials such as CFRP, ceramics, glass, and non-ferrous metals. Diamond coatings reduce cutting resistance and wear while ensuring precise hole size and superior surface finish, making them ideal for advanced precision machining.

Threading

Threading Series is designed for precise, reliable, and efficient internal and external thread machining across a wide range of materials. Developed for high-performance CNC applications, it delivers excellent thread accuracy, stable cutting performance, and long tool life, making it suitable for automotive, aerospace, mold making, machinery parts, and general engineering.This series focuses on high-precision threading tools with optimized geometry and advanced materials to reduce cutting resistance, ensure smooth chip evacuation, and maintain tight dimensional tolerances. It provides consistent and stable performance for both mass production and small-batch machining.Machine Taps are specifically engineered for CNC and automated tapping. Made from premium HSS, cobalt alloys, or solid carbide, they offer high wear and heat resistance. Optimized flute designs prevent chip jamming and thread deformation. Available in spiral flute, spiral point, and straight flute types, they are suitable for materials such as stainless steel, hardened steel, aluminum, copper, and cast iron, ensuring accurate threads, lower torque, and extended service life.

Collets

Collet Series is designed to meet diverse high-precision clamping requirements for CNC lathes, machining centers, and automatic bar-feeding systems. It includes Guide Bushes, Lathe Collets, Barfeed Collets, and ER Collets, providing complete solutions for precision turning, drilling, and automated machining.All collets are made from high-quality materials and finished with precision grinding to ensure excellent concentricity, strong clamping force, and long service life. This reduces runout, improves machining accuracy, and enhances tool stability in both small-part machining and high-speed mass production.With reliable performance and strict quality control, the Collet Series is widely applied in mold making, automotive parts, electronics, and precision engineering industries.

- Solution

- Service