What is a Thread End Mill - Insight

Thread Milling Cutter: A Comprehensive Overview

The traditional thread processing methods are mainly using thread turning tool to turn the thread or using tap, die hand tapping and sleeve.

With the development of CNC machining technology, especially the appearance of three-axis CNC machining system, a more advanced thread machining mode - CNC milling of threads has been realized.

Compared with the traditional thread processing method, thread milling has great advantages in processing accuracy and processing efficiency,

and the processing is not limited by the thread structure and thread direction, such as a thread milling cutter can process a variety of internal and external threads with different directions.

For threads that are not allowed to have transition buckle or escrape, it is difficult to process using traditional turning methods or taps and dies, but it is very easy to achieve using CNC milling.

In addition, the durability of the thread milling cutter is more than ten times or even dozens of times that of the tap, and in the process of CNC milling thread,

the adjustment of the diameter of the thread is extremely convenient, which is difficult to do with the tap and die.

Because of the many advantages of thread milling, milling process has been widely used in mass thread production in developed countries.

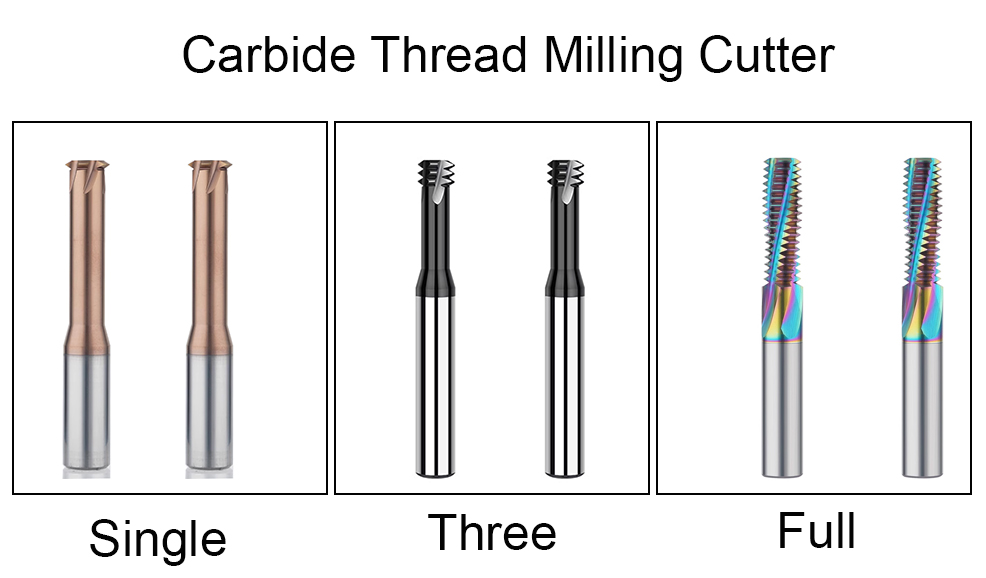

Thread Milling Classification

Thread milling cutters can be simply divided into three categories, single tooth thread end mill;three tooth thread end mill; full tooth tooth thread end mill.

There are also special thread milling cutter types: Drilling And Milling Thread Milling Cutter; Taper Medical Bone Plate Thread Milling Cutter;

29 ° Acme Female Thread Milling.... More types. Special thread milling cutter, we will introduce later. Now mainly introduces three commonly used thread milling.

Single Tooth Thread End Mill

Affordable price, a wide range of processing

Can process different pitch and any straight handle of the inner and outer screw threads, no turning direction restrictions.

And can process blind holes, reduce purchasing costs.

Three Tooth Thread End Mill

High cost performance, advantage than single thread milling cutter speed

Head teeth milling and the back two teeth trimming, fixed pitch machining, not adjustable.

With keep-space design.

Full Tooth Thread End Mill

One milling can be formed, high efficiency.

Suitable for efficient processing of large quantities of threads.

Fixed tooth spacing, not adjustable.

Conclusion:

Reasonable choice of tool processing, choose the corresponding coating according to different materials. It can improve machining efficiency and extend tool life.

Thread milling technology is increasingly widely used in machinery manufacturing, which promotes the development of the industry.

The application of thread milling requires attention to the appropriate workpiece shape, a favorable machining scheme and a thread milling cutter of reliable quality.

Only through the comprehensive use of thread milling technology, can give full play to the advantages of thread milling processing and achieve results.

At the same time, it also makes the machine performance show incisively and vividly, and promotes the production capacity of thread milling cutter.

INSIGHT is a brand under Shenzhen Chenri Precision Hardware Tools Co., Ltd.. We specialize in the production of a wide range of hard alloy turning tools,

hard alloy end mills, hard alloy drill bits, cutting tools, and Swiss collets. Our products cover a wide spectrum of metal cutting applications.

If you have any questions about thread milling, please contact us